We provide quality products at competitive prices!

NEW Completely Sealed Construction

These high-quality sealed band and strip heaters feature a 304 stainless steel flat tube construction weld sealed at the ends for maximum resistance to moisture, contamination, and corrosion. The internal elements are totally embedded in highly compacted, high temperature ceramic insulation.

Performance benefits include:

Higher temperature and wattage capabilities, improved heat uniformity, reduced thermal mass, and increased heating efficiency. Sealed band and strip heater assemblies requiring holes are also readily manufactured. Our exclusive hole forming process expands the inner sheath into an eyelet which extends through the hole and is weld sealed at the outer sheath maintaining the totally sealed construction. Special features including distributed wattage, multiple independent heat zones and internal temperature sensors are easily added.

Efficient and Cost Effective

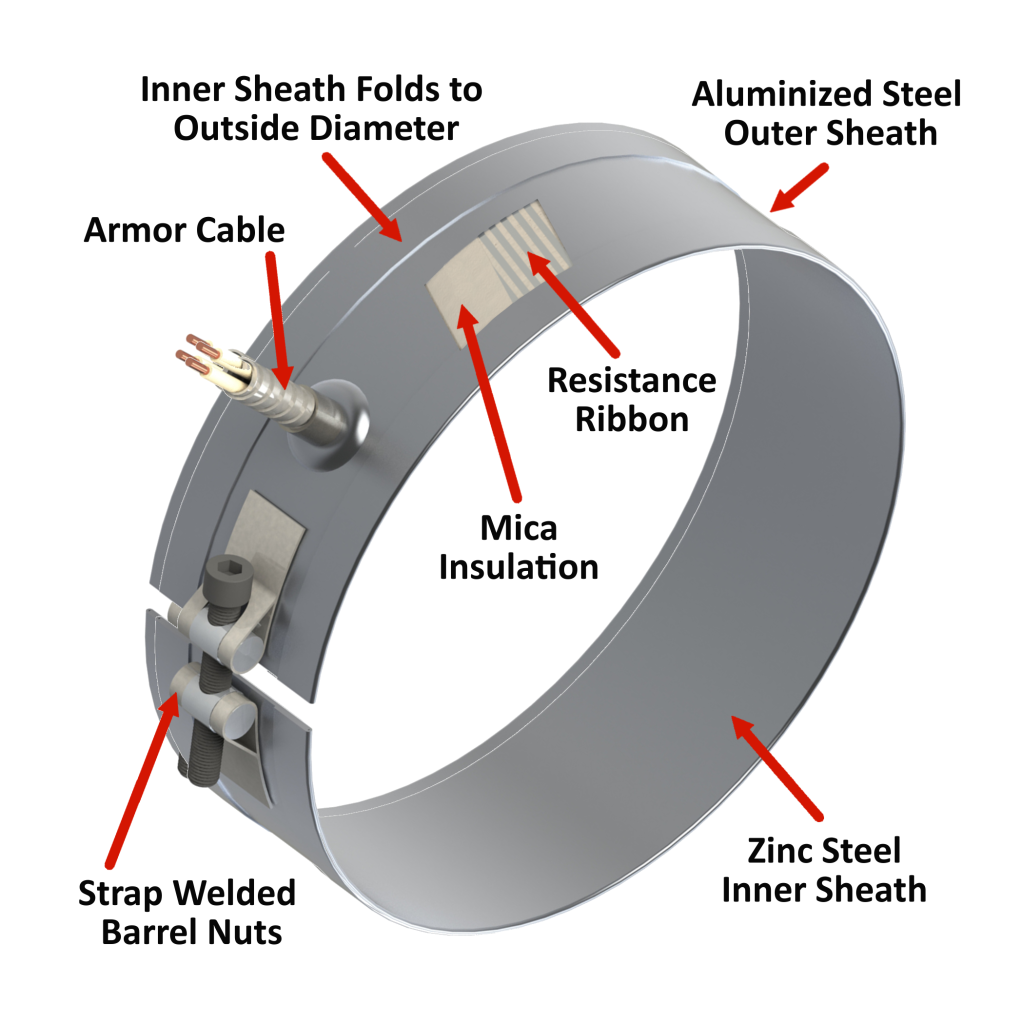

MICA band heaters are constructed with a mica core wound with wire. The core is then bent into a circle band. Leads are attached before the final outer sheaths are attached to complete the heater. Our MICA band heaters can be installed directly onto barrel heaters without the requirement of initial heater removal, they only require one set of leads or terminals, and are assembled with polished precision.Efficient Heat Transfer

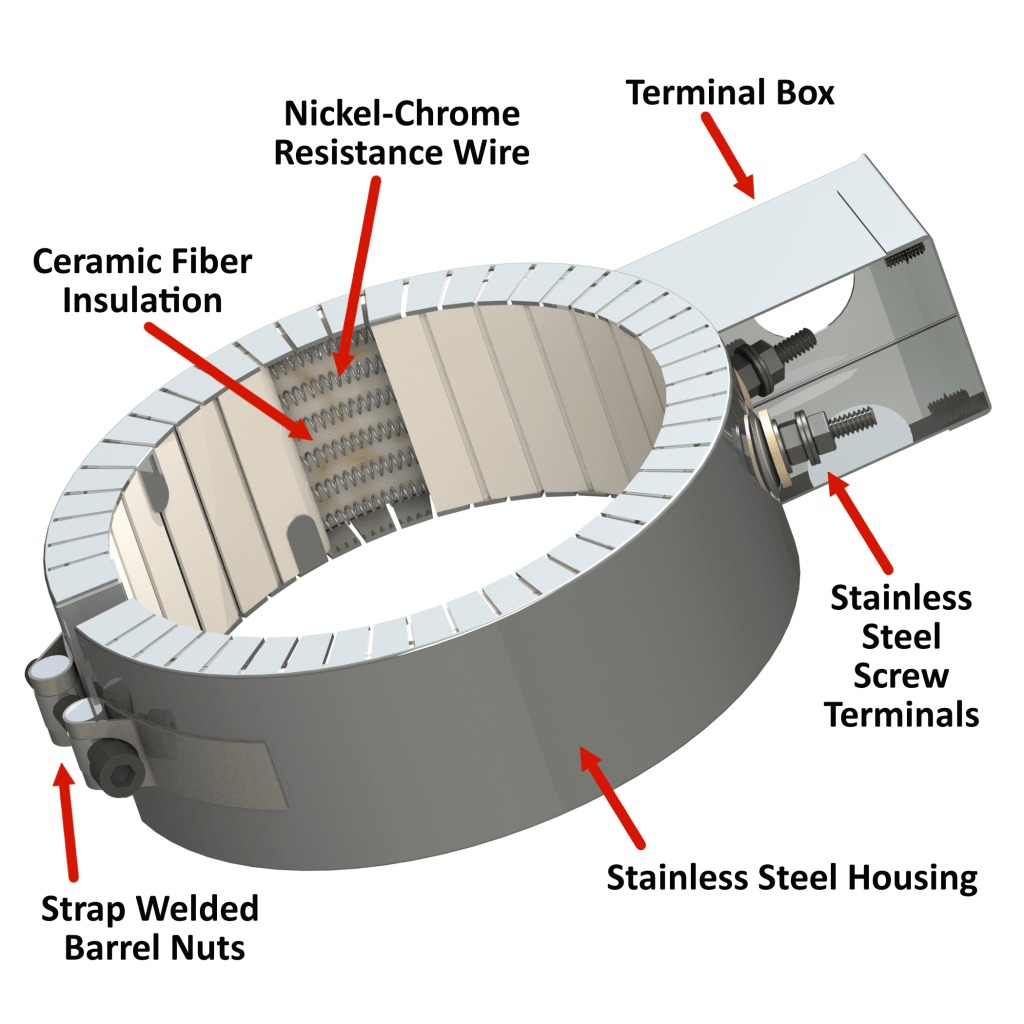

Ceramic band heaters offer a flexible heating system that yields efficient transmission of conduction and radiated heat. The heat of the ceramic band originates from the inner coils that conduct heat at maximum temperatures. Ceramic band diagrams show the heated coils that evenly deliver heat through the ceramic tiles, which radiate energy to the barrel. We offer a variety of ceramic band styles from standard to custom configurations.

.jpeg)

Durable and Long Lasting

The element utilized within alluminum band heaters is the highly efficent, rugged, and long lasting tubular heater pressed in a grooved aluminum extrusion. The combination of the tubular heater in exact contact with the excellent thermal conducting aluminum extrusion create a quick responding band heater with uniform sheath temperatures for precise process heating. With sheath temperatures to 650oF attainable, the Aluminum Heater is ideal for use on barrels of plastic extruders, injection molding machines, dies and die heads of extruders and blow molding equipment, or, within temperature limitations, any cylindrical surface.

Durable and Multifunctional

Strip Heaters with backer plates can help ensure a high quality contact. They are capable of all type of configurations, designs, and lead types.

Request a Quote

Fill out some basic information and we'll get back to you with an estimate as soon as possible.